Product overview

CB series permanent magnet synchronous motor for the current replacement of three-phase asynchronous motor energy saving efficiency suitable configuration products, on the basis of integrated synchronous motor servo function, can be with the original standard (Y1/Y2) series asynchronous motor installation size common, to provide customers with more efficient, energy-saving, complete replacement products. All CB series permanent magnet synchronous motors of our company have obtained the first class permanent magnet energy efficiency certification.

CB series permanent magnet synchronous motor main advantages:

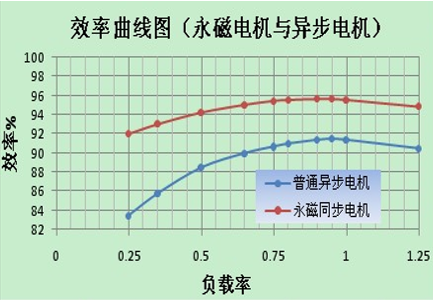

High efficiency: CB series permanent magnet synchronous motor at the same power at the same speed can achieve asynchronous motor level one energy efficiency, its external characteristic efficiency curve compared with three-phase asynchronous motor, in light load efficiency value is higher than asynchronous motor 20%.

High power factor: CB series permanent magnet synchronous motor does need exciting rotor, high efficiency, high power factor, the power factor can be adjusted, limited by the number of motor poles. In contrast, asynchronous motors, due to their own excitation characteristics, will lead to lower lower power factor as the number of poles increases.

High power density: CB series permanent magnet synchronous motor with the increase of efficiency, the corresponding loss is reduced, while the motor temperature rise is reduced, under the same frame, the power is twice as big as the asynchronous motor;

Simple debugging: Because CB series permanent magnet synchronous motor parameters are limited by the number of motor poles, it increases the flexibility of mechanical transmission system design, no slip during operation, better speed regulation performance.

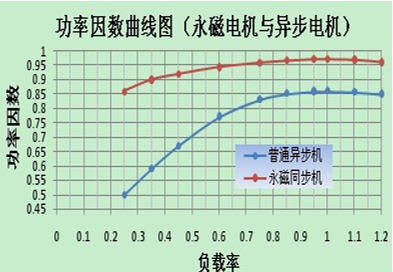

Type description

For example:

CB176F22-030

Frame number: 176

Cooling method: air cooling

Power: 22kW

Speed: 3000RPM

4. Technical parameters dimensions

CB Series 750rpm

CB Series 1000rpm

CB Series 1500rpm

CB Series 3000rpm (with technical parameters size table, outline size drawing)

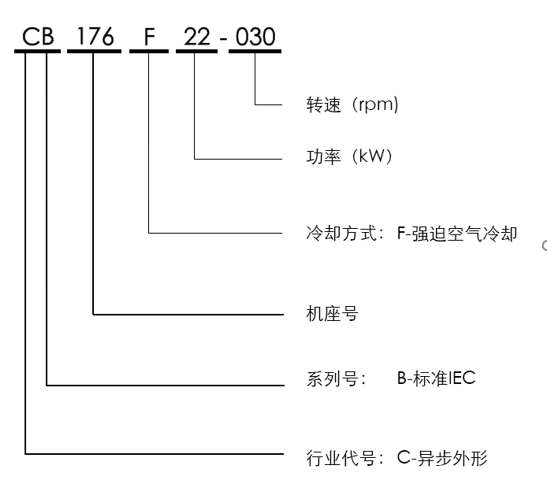

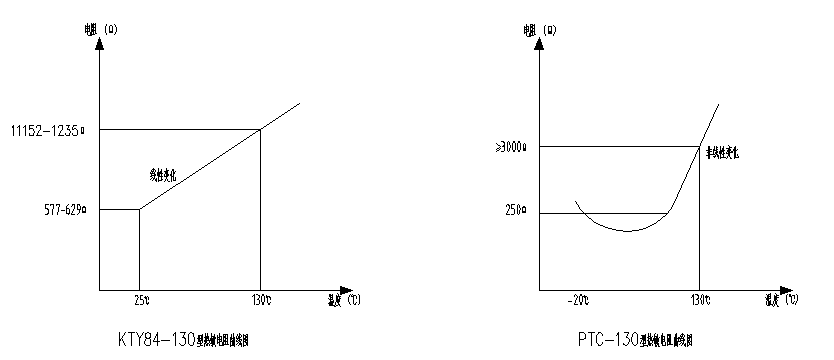

5. Temperature protection

1, motor internal temperature protection standard configuration: none

2, optional configuration: PTC130, KTY84, PT100 temperature sensitive switch

6. Encoder configuration

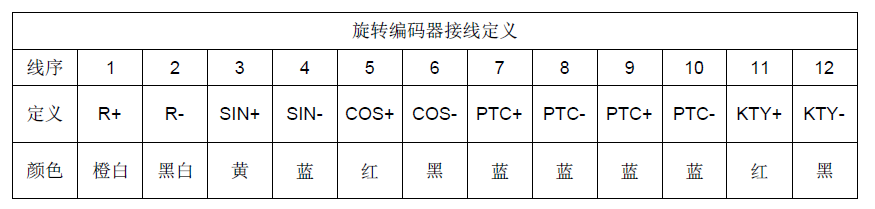

1. The standard feedback device used by De Neng motor is the rotary encoder (win double, how Chuan); Attached map

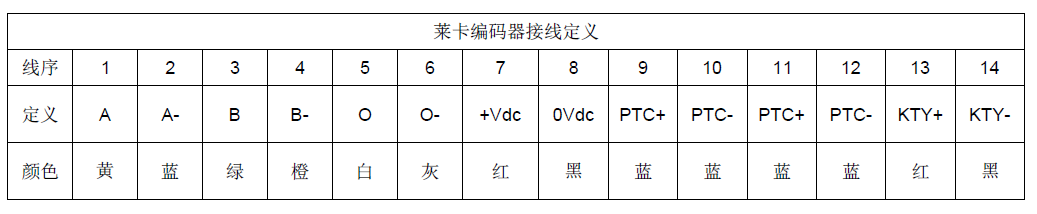

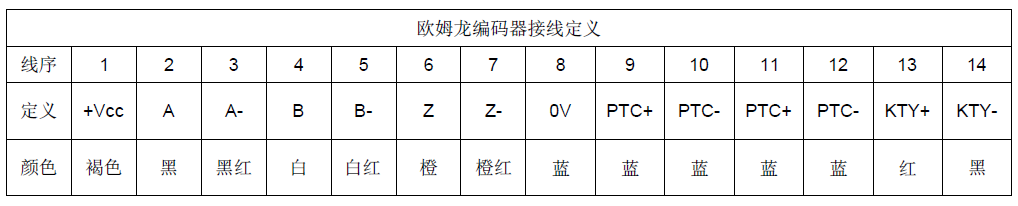

2. Incremental encoders (Leica, Omron) can also be configured. Attached map

Seven, wiring terminals

● The layout of terminals in the motor terminal box shall be subject to the actual object.

● The power cord connected to the motor should be too thin too long. The motor should be properly grounded.

● The motor should be connected strictly according to the provided power supply encoder wiring diagram.

● Connect the power supply, the driver the motor, so that the motor idling, the motor steering the shaft extension end is regarded as clockwise (positive).

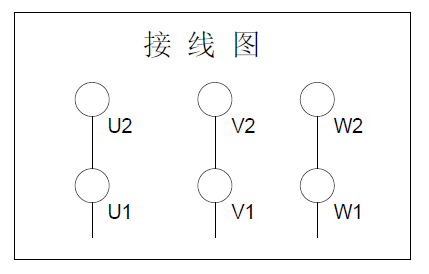

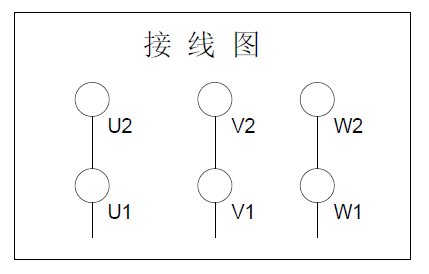

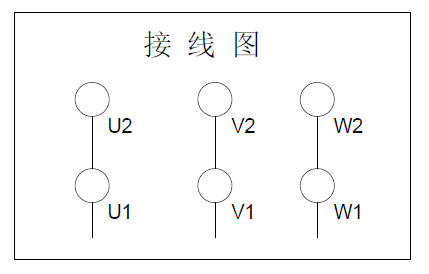

Wiring diagram: Power terminal: U, V, W corresponding to blue, red, yellow;

1, CB series motor wiring definition diagram:

2, CB series motor cooling fan wiring definition diagram:

3, CB series temperature sensor encoder wiring definition diagram:

8. Operation maintenance

1. The ambient temperature used by the motor is -15 ~ 40℃, the altitude does exceed 1000m. Dustproof waterproof requirements must be consistent with the protection level of the motor housing.

2. Environmental conditions: Working environment air pressure: 86-106kPa, storage environment temperature: -40~50 ℃ Working environment temperature: -15 ~ 40 ℃ Relative humidity of air: storage environment relative humidity: ≤93%, working environment relative humidity: 40~ 80%(no condensation).

3. The motor shall be used in an environment containing flammable gases, chemically corrosive gases other harmful gases.

4. The surface of the motor should be cleaned regularly kept clean regularly to ensure that the inlet, outlet air duct are blocked.

5. Keep the inside of the motor clean, do allow water droplets, oil debris into the motor.

6. If the motor is found abnormal during operation, such as abnormal sound, overheating, burnt taste, it should be stopped immediately for inspection, can be used after the fault is removed.

7. CB series permanent magnet synchronous motor adopts closed bearings below the 260 frame, does need to change the grease during the service life, adopts open bearings above the 260 frame, which requires regular oil filling. See the motor label for details.

8. In order to ensure the normal operation of the motor, a small amount of anti-wear oil should be regularly added to the oil seal ( shaft joint surface), the effect of using high-temperature grease is better; At the same time, the motor should be regularly checked according to the actual situation.

9. When the motor is used in the warehouse, it should be properly packaged stored, kept ventilated dry to avoid moisture rust of the motor. If there is condensation in the storage environment, it should be drained regularly.

9. Motor model selection table

See the attachment